I-PCB (Printed Circuit Board) iyisisekelo sezinto zikagesi, ezivumela ukuxhumana nokugeleza kukagesi phakathi kwezingxenye ezihlukahlukene. Noma ngabe ungumuntu othanda izinto zikagesi noma uchwepheshe, ukwazi ukuthi udala kanjani amasekhethi e-PCB kuyikhono elibalulekile elingathuthukisa amaphrojekthi akho obuchwepheshe. Kule bhulogi, sizohlinzeka ngomhlahlandlela wesinyathelo ngesinyathelo sendlela yokwenza isekethe ye-PCB.

1. Idizayini nokudalwa kohlelo:

Isinyathelo sokuqala ekwenzeni isekethe ye-PCB ukudizayina nokudala uhlelo. Usebenzisa isofthiwe yokuklama isikimu, njenge-Eagle noma i-KiCad, dweba umdwebo wesifunda. Ukubekwa ngokucophelela kwezingxenye, isakhiwo esilungile esiqinisekisa ukuhamba okunengqondo kwamasignali kanye nomzila ophumelelayo kubalulekile.

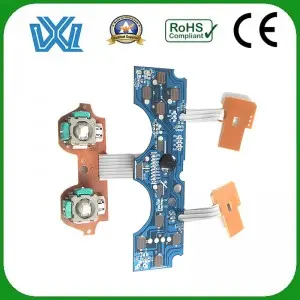

2. Isakhiwo se-PCB:

Uma isikimu sesiphelile, isinyathelo esilandelayo ukwakha isakhiwo se-PCB. Le nqubo ibandakanya ukudlulisa izingxenye nokuxhumana kusuka kuhlelo kuya ekwakhiweni kwebhodi elibonakalayo. Qondanisa izingxenye namaphakheji azo, uqinisekise ukuma okulungile nokugcina isikhala esifanele ukugwema ukuphazamiseka.

3. Ukufakwa kwamapuleti:

Uma isakhiwo se-PCB sesiqediwe, sekuyisikhathi sokuqopha ibhodi. Okokuqala phrinta umklamo webhodi lesifunda ephepheni elikhethekile lokudlulisa usebenzisa iphrinta ye-laser. Beka okuphrintiwe ku-PCB egqoke ithusi bese uyishisa ngensimbi noma nge-laminator. Ukushisa kudlulisa uyinki kusuka ephepheni kuya ebhodini, kwakha ungqimba oluvikelayo emithonjeni yethusi.

4. Inqubo yokunamathisela:

Uma ukudlulisa sekuqediwe, sekuyisikhathi sokuqopha ibhodi. Lungiselela isitsha esinesixazululo esifanelekile sokuhlanganisa (njenge-ferric chloride) bese ucwilisa ibhodi kuso. Gcoba ngobumnene isisombululo ukuze ususe ithusi eliningi ezindaweni ezingavikelekile, ushiye kuphela iminonjana oyifunayo. Phakathi nale nqubo, qiniseka ukuthi uthatha izinyathelo zokuphepha ezifana nokugqoka amagilavu nezibuko, njengoba isixazululo se-etching singaba yingozi.

5. Ukumba:

Ngemuva kokucwiliswa, izimbobo zidinga ukubhobozwa ukuze kubekwe izingxenye. Sebenzisa i-drill enencanyana encane efana nosayizi wengxenye yokuhola. Geza ngokucophelela ezindaweni ezikhethiwe bese uqinisekisa ukuthi izimbobo zihlanzekile futhi azinayo imfucumfucu.

6. Ukushisela:

Ngemuva kokuthi ibhodi liqoshwe futhi kwabholwa izimbobo, sekuyisikhathi sokuthengisa izingxenye ku-PCB. Qala ngokuxhuma izingxenye emigodini yazo, uqiniseke ukuthi zihlezi ngokuphephile. Phenya ibhodi futhi uthengise ingxenye ngayinye, usebenzise ukushisa ukuze uncibilikise intambo ye-solder futhi wenze isibopho esiqinile. Sebenzisa i-solder iron iron kanye ne-flux ukuze uzuze amalunga ahlanzekile, athembekile.

7. Isivivinyo:

Ngemuva kokuhlanganisa zonke izingxenye, ukusebenza kwesifunda kufanele kuhlolwe. Sebenzisa i-multimeter ukuze uhlole ukuqhubeka kokulandelela futhi uqinisekise ukuxhumana okufanele. Futhi, yenza ukuhlolwa okubonakalayo ukuze uqiniseke ukuthi awekho amabhuloho e-solder noma amalunga abandayo.

Ekuphetheni:

Ukudala amasekhethi e-PCB kungase kubonakale kunzima ekuqaleni, kodwa ngolwazi olufanele namathuluzi, kungaba umsebenzi ofinyelelekayo. Ngokulandela umhlahlandlela wesinyathelo ngesinyathelo onikezwe kule bhulogi, ungenza ngokuzethemba amasekhethi e-PCB kumaphrojekthi akho kagesi. Khumbula, ukuzijwayeza kwenza kuphelele, ngakho-ke ungadikibali uma kuthatha imizamo embalwa ukuze uthole i-hang yenqubo. Ngokuhamba kwesikhathi nolwazi, uzokwazi ukudala ngempumelelo amasekhethi e-PCB ayinkimbinkimbi futhi asebenza kahle kakhulu.

Isikhathi sokuthumela: Jul-07-2023