Ngokwezifiso PCB Assembly kanye PCBA

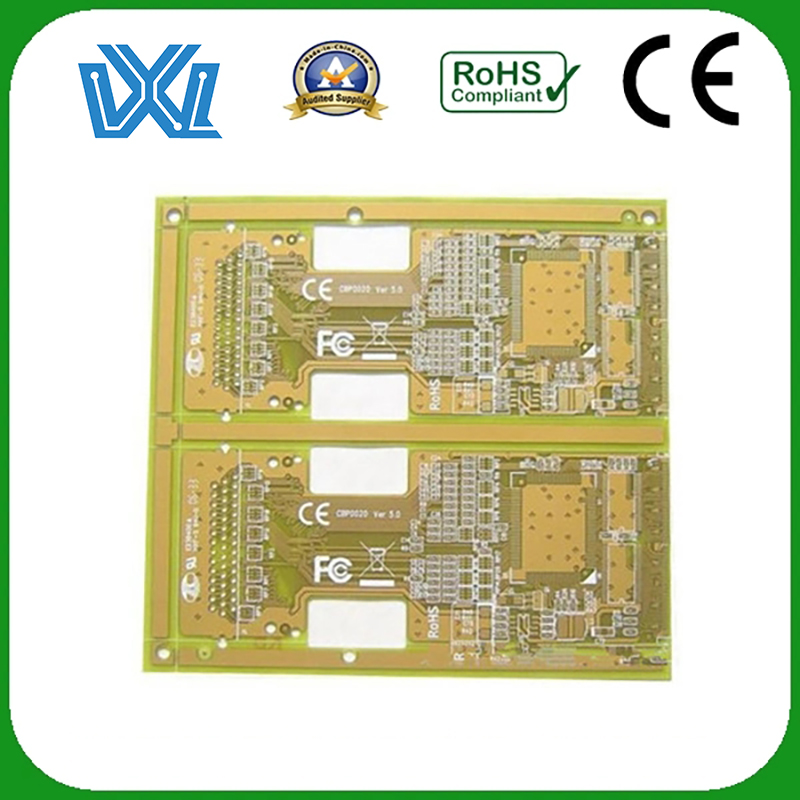

Incazelo

| Inombolo yemodeli. | I-ETP-005 | Isimo | Okusha |

| Uhlobo Lomkhiqizo | I-PCB Assembly kanye ne-PCBA | Min.Hole Usayizi | 0.12mm |

| Umbala Wemaski Solder | Okuluhlaza, Okuluhlaza okwesibhakabhaka, Okumhlophe, Okumnyama, Okuphuzi, Okubomvu njll I-Surface Qeda | I-Surface Qeda | HASL, Enig, OSP, Gold Finger |

| I-Min Trace Width/Space | 0.075/0.075mm | Ukuqina Kwethusi | 1 – 12 Oz |

| Izindlela Zomhlangano | SMT, DIP, Through Hole | Inkambu yohlelo lokusebenza | I-LED, Medical, Industrial, Control Board |

Mayelana ne-PCB Board Design yethu

Lapho siklama ibhodi le-PCB, siphinde sibe nesethi yemithetho: okokuqala, hlela izikhundla zengxenye eyinhloko ngokwenqubo yesignali, bese ulandela "umjikelezo wokuqala onzima bese ulula, ivolumu yengxenye kusukela enkulu kuya encane, isignali eqinile futhi ukuhlukaniswa kwesignali okubuthakathaka, okuphezulu nokuphansi. Amasignali ahlukene, amasignali ahlukene e-analog kanye nedijithali, zama ukwenza izintambo zibe zifushane ngangokunokwenzeka, futhi wenze isakhiwo sibe esinengqondo ngangokunokwenzeka”; ukunakekelwa okukhethekile kufanele kukhokhwe ukuze kuhlukaniswe "indawo yesignali" kanye "nendawo yamandla"; lokhu ikakhulukazi ukuvimbela indawo yamandla Ulayini ngezinye izikhathi unomsinga omkhulu odlula kuwo. Uma lokhu kwamanje kwethulwa kutheminali yesignali, kuzobonakala kutheminali yokuphumayo nge-chip, ngaleyo ndlela kuthinte ukusebenza kokulawulwa kwamandla kagesi wokushintshwa kwamandla.

Khona-ke, isikhundla sokuhlelwa kanye nokuqondisa kwezintambo zezingxenye kufanele kuhambisane ngangokunokwenzeka ne-wiring yomdwebo wesifunda, okuzoba lula kakhulu ukulungiswa nokuhlolwa kamuva.

Intambo yaphansi kufanele ibe mfushane futhi ibe banzi ngangokunokwenzeka, futhi intambo ephrintiwe edlula umsinga oshintshanayo kufanele futhi inwetshwe ngangokunokwenzeka. Ngokuvamile, sinesimiso lapho sifaka izintambo, intambo yaphansi ibanzi kakhulu, intambo yamandla ingeyesibili, futhi intambo yesiginali incane kakhulu.

Nciphisa iluphu yempendulo, indawo yeluphu yokuhlunga okokufaka kanye nokulungisa okukhiphayo ngangokunokwenzeka, le njongo iwukunciphisa ukuphazamiseka komsindo wokushintshwa kwamandla kagesi.

One-stop Solution

Amadivayisi angenisayo njengama-thermistors kufanele agcinwe kude ngangokunokwenzeka nemithombo yokushisa noma amadivaysi esekethe abangela ukuphazamiseka.

Ibanga elilinganayo phakathi kwama-chips akulayini amabili kufanele libe likhulu kuno-2mm, futhi ibanga phakathi kwesiphikisayo se-chip ne-chip capacitor kufanele libe likhulu kuno-0.7mm.

I-capacitor yesihlungi sokufaka kufanele ibekwe eduze ngangokunokwenzeka kulayini odinga ukuhlungwa.

Ekwakhiweni kwebhodi le-PCB, izinkinga ezivame kakhulu imithetho yokuphepha, i-EMC kanye nokuphazamiseka. Ukuze sixazulule lezi zinkinga, kufanele sinake izici ezintathu lapho siklama: ibanga lesikhala, ibanga le-creepage kanye nebanga lokungena lokungena. Umthelela.

Isibonelo: Ibanga le-Creepage: lapho i-voltage yokufaka ingu-50V-250V, i-LN phambi kwe-fuse ingu-≥2.5mm, lapho i-voltage yokufaka ingu-250V-500V, i-LN phambi kwe-fuse ingu-≥5.0mm; imvume kagesi: lapho i-voltage yokufaka ingu-50V-250V, L—N ≥ 1.7mm phambi kwe-fuse, lapho i-voltage yokufaka ingu-250V-500V, L—N ≥ 3.0mm phambi kwefuse; akukho mfuneko edingekayo ngemva kwe-fuse, kodwa zama ukugcina ibanga elithile ukuze ugweme ukulimala kwesifunda esifushane kugesi; ingxenye eyinhloko ye-AC kuya ku-DC ≥ 2.0 mm; ohlangothini oluyinhloko lwe-DC phansi kuya phansi ≥4.0mm, njengohlangothi oluyisisekelo kuya phansi; ohlangothini oluyinhloko kuya ohlangothini lwesibili ≥6.4mm, njenge-optocoupler, i-Y capacitor nezinye izingxenye zengxenye, isikhala sephini singaphansi noma silingana no-6.4mm okufanele sifakwe; i-transformer enezigaba ezimbili ≥6.4mm noma ngaphezulu, ≥8mm yokufakwa okuqinisiwe.

Umbukiso Wemboni

FAQ

Q1: Uqinisekisa kanjani ikhwalithi yama-PCB?

A1: Ama-PCB ethu wonke awu-100% wokuhlola okuhlanganisa i-Flying Probe Test, i-E-test noma i-AOI.

Q2: Iyini isikhathi sokuhola?

I-A2: Isampula idinga izinsuku zokusebenza ezingu-2-4, ukukhiqizwa ngobuningi kudinga izinsuku zokusebenza ezingu-7-10. Kuncike kumafayela nenani.

Q3: Ngingathola intengo engcono kakhulu?

A3: Yebo. Ukusiza amakhasimende ukulawula izindleko yilokho esihlala sizama ukukwenza. Onjiniyela bethu bazohlinzeka ngomklamo ongcono kakhulu wokugcina impahla ye-PCB.