PCByenziwe ngeteknoloji yoshicilelo lwe-elektroniki, ngoko ibizwa ngokuba yibhodi yesekethe eprintiweyo. Phantse lonke uhlobo lwezixhobo zombane, ukusuka kwii-earphones, iibhetri, calculators, ukuya kwiikhompyuter, izixhobo zonxibelelwano, iinqwelomoya, iisathelayithi, okoko nje kusetyenziswe izinto zombane ezinje ngeesekethe ezidityanisiweyo, iiPCB zisetyenziselwa uqhagamshelo lombane phakathi kwazo.

I-PCB kunye ne-PCBA yi-PCB enamacandelo anganyukanga, i-PCBA (iNdibano yeBhodi yeSekethe eShicileleyo), oko kukuthi, ii-PCB ezixhotyiswe ngamacandelo e-elektroniki (njengeetshiphusi, izihlanganisi, i-resistors, i-capacitors, i-inductors, njl.).

Imvelaphi yePCB

Ngomnyaka we-1925, uCharles Ducas eUnited States (umsunguli wendlela yokongeza) washicilela ipateni yesiphaluka kwi-substrate ekhuselayo, kwaye emva koko wenza ngempumelelo umqhubi njenge-wiring nge-electroplating.

Ngowe-1936, uPaul Eisler waseAustria (umsunguli wendlela yokuthabatha) wayengowokuqala ukusebenzisa iibhodi zesekethe eziprintiweyo koonomathotholo.

Ngowe-1943, abantu baseMerika basebenzisa itekhnoloji koonomathotholo basemkhosini. Ngowe-1948, iUnited States yavuma ngokusemthethweni ukuveliswa korhwebo.

Iibhodi zeesekethe eziprintiweyo zisetyenziswe ngokubanzi kuphela ukususela phakathi kwe-1950s, kwaye namhlanje zilawula ishishini lombane.

Iibhodi zesekethe eziprintiweyo ziye zaphuhliswa ukusuka kuluhlu olulodwa ukuya kumacala amabini, ulwaleko oluninzi kunye nokuguquguquka, kwaye zisagcina ezazo iindlela zophuhliso. Ngenxa yophuhliso oluqhubekayo kwicala lokuchaneka okuphezulu, ukuxinana okuphezulu kunye nokuthembeka okuphezulu, ukunciphisa ngokuqhubekayo ubungakanani, ukunciphisa iindleko kunye nokuphucula ukusebenza, iibhodi zeesekethe eziprintiweyo zisagcina amandla omelele kuphuhliso lwezixhobo ze-elektroniki zexesha elizayo.

Iingxoxo ngekamva lophuhliso lwetekhnoloji yokuvelisa ibhodi yesekethe eprintiweyo ekhaya nakwamanye amazwe ngokusisiseko ziyahambelana, oko kukuthi, ukuxinana okuphezulu, ukuchaneka okuphezulu, indawo yokuvula ecolekileyo, ucingo olubhityileyo, isandi esincinci, ukuthembeka okuphezulu, umaleko omninzi, ukuhanjiswa kwesantya esiphezulu. , Ubunzima obulula Ngokubhekiselele kwimveliso, iphuhlisa kwicala lokunyusa imveliso, ukunciphisa iindleko, ukunciphisa ukungcola, kunye nokulungelelanisa kwiintlobo ezininzi kunye nemveliso encinci.

Indima yePCB

Ngaphambi kokuba ibhodi yesekethe eprintiweyo ibonakale, uqhagamshelwano phakathi kwamacandelo e-elektroniki ludityaniswe ngokuthe ngqo ngeengcingo ukwenza isiphaluka esipheleleyo.

Emva kokuba izixhobo ze-elektroniki zamkele iibhodi zeesekethe eziprintiweyo, ngenxa yokuhambelana kweebhodi zeesekethe eziprintiweyo ezifanayo, iimpazamo kwi-wiring manual ziyagwenywa.

Ibhodi yesekethe eprintiweyo inokubonelela ngenkxaso yomatshini yokulungisa kunye nokudibanisa izinto ezahlukeneyo ze-elektroniki ezifana neesekethe ezidibeneyo, ukugqiba i-wiring kunye nokudibanisa kombane okanye ukufakwa kombane phakathi kwezinto ezahlukeneyo ze-elektroniki ezifana neesekethe ezidibeneyo, kunye nokubonelela ngeempawu zombane ezifunekayo, ezifana neempawu Impedance, njl., inokubonelela ngemizobo yemaski ye-solder yokuthengisa ngokuzenzekelayo, kunye nokubonelela ngeempawu zokuchongwa kunye nemizobo yokufakwa kwecandelo, ukuhlolwa, kunye nokugcinwa.

Ukuhlelwa kwePCB

1. Ukuhlelwa ngokwenjongo

Iibhodi zesekethe eziprintiweyo zasekuhlaleni (umthengi): iibhodi zesekethe eziprintiweyo ezisetyenziswa kwizinto zokudlala, iikhamera, oomabonakude, izixhobo zomsindo, iiselfowuni, njl.njl.

Iibhodi zesekethe eziprintiweyo kwishishini (izixhobo): iibhodi zeesekethe eziprintiweyo ezisetyenziselwa ukhuseleko, iimoto, iikhompyuter, oomatshini bonxibelelwano, izixhobo, njl.

Iibhodi zeesekethe eziprintiweyo zomkhosi: iibhodi zeesekethe eziprintiweyo ezisetyenziswa kwi-aerospace kunye ne-radar, njl.

2. Ukuhlelwa ngokohlobo lwe-substrate

Iibhodi zeesekethe eziprintiweyo ezisekelwe kwiphepha: iibhodi zesekethe eziprintiweyo zephenolic ezisekelwe kwiphepha, iibhodi zesekethe eziprintiweyo ze-epoxy, njl.

Iibhodi zesekethe eziprintiweyo ezisekelwe kwilaphu leglasi: iibhodi zesekethe eziprintiweyo zeglasi epoxy ngelaphu, iibhodi zesekethe eziprintiweyo zeglasi yePTFE, njl.

Ibhodi yesekethe eprintiweyo yefayibha: ibhodi yesekethe ye-epoxy synthetic fiber eprintiweyo, njl.

I-Organic film substrate eprintwe ibhodi yesekethe: ifilimu yenylon eprintwe ibhodi yesekethe, njl.

Iibhodi zeesekethe eziprintiweyo zeCeramic substrate.

Metal core esekelwe iibhodi zesekethe eprintiweyo.

3. Ukuhlelwa ngokwesakhiwo

Ngokwesakhiwo, iibhodi zesekethe eziprintiweyo zinokwahlulwa zibe ziibhodi zesekethe eziprintiweyo eziqinileyo, iibhodi zesekethe eziguquguqukayo eziprintwayo kunye neebhodi zesekethe eziguquguqukayo.

4. Ihlelwe ngokwenani leeleya

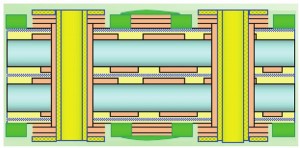

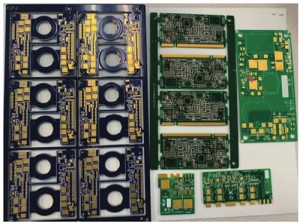

Ngokwenani leengqimba, iibhodi zeesekethe eziprintiweyo ziyakwazi ukwahlula kwiibhodi ezihlangeneyo, iibhodi ezinamacala amabini, iibhodi ze-multi-layer kunye neebhodi ze-HDI (iibhodi ze-high-density interconnect).

1) Icala elinye

Ibhodi enecala elilodwa libhekisela kwibhodi yesekethe edibeneyo kwicala elinye kuphela (icala le-soldering) lebhodi yesiphaluka, kwaye zonke iinqununu, iileyibhile zecandelo kunye nemibhalo ebhaliweyo zibekwe kwelinye icala (icala lecandelo).

Eyona nto inkulu yephaneli yecala elilodwa lixabiso layo eliphantsi kunye nenkqubo yokuvelisa elula. Nangona kunjalo, ekubeni i-wiring inokuqhutyelwa kuphela kwindawo enye, i-wiring inzima kakhulu, kwaye i-wiring ixhomekeke ekungaphumeleli, ngoko ifanelekile kuphela kwiisekethe ezilula.

2) Icala eliphindwe kabini

Ibhodi ephindwe kabini ifakwe kumacala omabini ebhodi yokukhusela, elinye icala lisetyenziswe njengoluhlu oluphezulu, kwaye elinye icala lisetyenziswe njengoluhlu oluphantsi. Umaleko ongaphezulu nasezantsi uqhagamshelwe ngombane nge-vias.

Ngokuqhelekileyo, amacandelo ebhodini elinemigangatho emibini abekwe kwinqanaba eliphezulu; nangona kunjalo, ngamanye amaxesha amacandelo anokubekwa kuzo zombini iileya ukwenzela ukunciphisa ubungakanani bebhodi. Ibhodi ye-double-layer ibonakaliswe ngexabiso eliphakathi kunye ne-wiring elula. Lolona hlobo lusetyenziswa ngokuqhelekileyo kwiibhodi zeesekethe eziqhelekileyo.

3) Ibhodi ye-Multi-layer

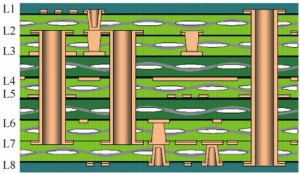

Iibhodi zeesekethe eziprintiweyo ezinamaleya angaphezu kwembini zibizwa ngokudibeneyo njengeebhodi ezininzi.

4) ibhodi ye-HDI

Ibhodi ye-HDI yibhodi yesekethe enoxinano oluphezulu lokusasazwa kwesekethe usebenzisa iteknoloji yomngxuma oyimfama oyimfama.

Ubume bePCB

I-PCB ikakhulu iqulunqwe ngeelaminates ezigqunywe ngobhedu (I-Copper Clad Laminates, CCL), i-prepreg (iphepha le-PP), i-copper foil (i-Copper Foil), imaski ye-solder (ekwaziwa ngokuba yi-solder mask) (I-Solder Mask). Kwangaxeshanye, ukuze kukhuselwe ifoyile yobhedu evezwayo phezu komhlaba kwaye uqinisekise isiphumo se-welding, kuyafuneka ukuba kwenziwe unyango olungaphezulu kwi-PCB, kwaye ngamanye amaxesha ikwaphawulwa ngeempawu.

1) I-Copper Clad Laminate

I-Copper-clad laminate (CCL), ebizwa ngokuba yi-copper-clad laminate okanye i-copper-clad laminate, iyona nto isisiseko sokuvelisa iibhodi zeesekethe eziprintiweyo. Iqulunqwe ngumaleko we-dielectric (i-resin, i-fiber yeglasi) kunye ne-conductor ephezulu (i-foil yobhedu). yenziwe ngezinto ezidibeneyo.

Kwada kwaba ngo-1960 ukuba abavelisi abaqeqeshiweyo basebenzisa ifoyile yobhedu ye-formaldehyde njengesiseko sokwenza iiPCB ezisecaleni, kwaye bazibeke kwimarike yabadlali berekhodi, abarekhoda beteyiphu, abarekhoda bevidiyo, njl njl. Kamva, ngenxa yokunyuka kabini Itekhnoloji yokuvelisa itekhnoloji yokwenziwa komngxunya yobhedu, ukumelana nobushushu, ubungakanani I-epoxy glass substrates ezizinzile zisetyenziswe ngokubanzi ukuza kuthi ga ngoku. Namhlanje, i-FR4, FR1, CEM3, iipleyiti ze-ceramic kunye neepleyiti zeTeflon zisetyenziswa ngokubanzi.

Okwangoku, i-PCB esetyenziswa kakhulu eyenziwe yindlela yokubhala kukukhetha i-etch kwibhodi yobhedu yobhedu ukufumana ipateni yesekethe efunekayo. I-laminate ye-copper clad inika ikakhulu imisebenzi emithathu yokuqhuba, ukugquma kunye nenkxaso kwibhodi yesekethe eprintiweyo yonke. Ukusebenza, umgangatho kunye neendleko zokuvelisa iibhodi zeesekethe eziprintiweyo zixhomekeke kumlinganiselo omkhulu kwiilaminates ezifakwe ubhedu

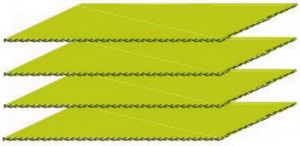

2) Prepreg

I-Prepreg, eyaziwa ngokuba yi-PP sheet, yenye yezinto eziphambili kwimveliso yeebhodi ezininzi. Ikakhulu yenziwe nge-resin kunye nezixhobo zokuqinisa. Izinto zokuqinisa zihlulwe zibe ilaphu lefiber yeglasi (ekubhekiselwa kuyo njengelaphu leglasi), isiseko sephepha kunye nezixhobo ezidibeneyo.

Uninzi lwama-prepregs (amaphepha anamathelayo) asetyenziselwa ukuveliswa kweebhodi zeesekethe eziprintiweyo ezininzi zisebenzisa i-glass cloth njengento yokuqinisa. Ilaphu elicekethekileyo elenziwe ngokufaka ilaphu leglasi elinyangisiweyo ngeglue yeresin, kwaye emva koko libhakwe kwangaphambili ngonyango lobushushu libizwa ngokuba yi-prepreg. I-Prepregs ithambisa phantsi kobushushu kunye noxinzelelo kwaye iqine xa ipholile.

Ekubeni inani lemisonto kwiyunithi yobude belaphu leglasi kwi-warp kunye ne-weft imiyalelo yahlukile, kufuneka kuqwalaselwe kwi-warp kunye ne-weft ye-prepreg xa usika. Ngokubanzi, ulwalathiso lwe-warp (isalathiso apho ilaphu leglasi ligotywe khona) likhethwa njengecala elifutshane lebhodi yemveliso, kunye nolwalathiso lwe-weft lu. umphezulu webhodi kwaye uthintele ibhodi yemveliso ukuba ijijwe kwaye ikhubazeke emva kokuba ishushu.

3) I-foil yobhedu

I-copper foil yintsimbi encinci, eqhubekayo efakwe kwisiseko sebhodi yesekethe. Njengomqhubi we-PCB, ibotshelelwa ngokulula kwi-insulating layer kwaye ifakwe ukwenza ipateni yesekethe.

Iifoyile zobhedu eziqhelekileyo zinokwahlulwa zibe ziindidi ezimbini: ifoyile yobhedu esongiweyo (ifoyile yobhedu yeRA) kunye nefoyile yobhedu ye-electrolytic (ifoyile yobhedu ye-ED):

I-foil yobhedu eqengqelekayo ine-ductility elungileyo kunye nezinye iimpawu, kwaye yifoyile yobhedu esetyenziswe kwinkqubo yebhodi ethambileyo yokuqala;

I-Electrolytic copper foil ine-advanteji yeendleko zokwenziwa eziphantsi kunefoyile yobhedu esongiweyo

4) Imaski yesolder

I solder ukumelana umaleko ibhekisela inxalenye ibhodi yesekethe eprintiweyo nge-inki yokuxhathisa solder.

I-inki yokuxhathisa i-Solder idla ngokuba luhlaza, kwaye abambalwa basebenzisa ebomvu, emnyama kunye neblue, njl., ngoko ke i-inki yokuxhathisa i-solder idla ngokuba yi-oyile eluhlaza kwishishini le-PCB. Ingumaleko osisigxina okhuselayo weebhodi zesekethe eziprintiweyo, ezinokuthintela ukufuma, i-Anti-corrosion, i-anti-mildew kunye ne-abrasion mechanical, njl., kodwa kwakhona ukuthintela iinxalenye ukuba zifakwe kwiindawo ezingalunganga.

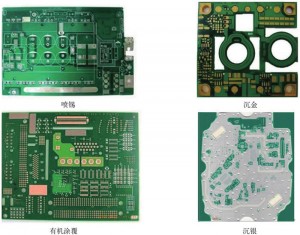

5) Unyango oluphezulu

“Umphezulu” njengoko usetyenziswe apha ubhekisa kwiindawo zoqhagamshelo kwi-PCB ezibonelela ngoqhagamshelo lombane phakathi kwezinto zombane okanye ezinye iisistim kunye neesekethe ezikwi-PCB, njengendawo yoqhagamshelo lweepads okanye uqhagamshelo loqhagamshelwano. I-solderability yobhedu olungenanto ngokwayo ilungile kakhulu, kodwa i-oxidized ngokulula kwaye ingcolile xa ibonakaliswe emoyeni, ngoko ifilimu ekhuselayo kufuneka ifakwe phezu kobhedu olungenanto.

Iinkqubo eziqhelekileyo zonyango ze-PCB zomphezulu ziquka i-HASL ekhokelayo, i-HASL engenalo ilothe, i-organic coating (i-Organic Solderability Preservatives, i-OSP), igolide yokuntywiliselwa, isilivere yokuntywiliselwa, i-tin yokuntywiliselwa kunye neminwe yegolide, njl. are Inkqubo ye-HASL ekhokelayo iye yavalwa ngokuthe ngcembe.

6) Abalinganiswa

Umlinganiswa ngumaleko wokubhaliweyo, kumaleko aphezulu we-PCB, inokungabikho, kwaye isetyenziswa ngokubanzi kwizimvo.

Ngokuqhelekileyo, ukwenzela ukuba kube lula ukufakwa kunye nokugcinwa kwesekethe, iipateni zelogo ezifunekayo kunye neekhowudi zetekisi ziprintwa kwiindawo eziphezulu kunye nezisezantsi zebhodi eprintiweyo, njengeelebhile zecandelo kunye namaxabiso aqhelekileyo, iimilo zecandelo kunye neelogo zomvelisi, imveliso. imihla ilinde.

Oonobumba badla ngokuprintwa ngokuprintwa kwesikrini

Ixesha lokuposa: Mar-11-2023