PCBe entsoe ka theknoloji ea khatiso ea elektronike, kahoo e bitsoa "printed circuit board". Hoo e ka bang mefuta eohle ea lisebelisoa tsa elektroniki, ho tloha ho li-earphone, libeteri, li-calculator, ho ea ho likhomphutha, lisebelisoa tsa puisano, lifofane, lisathelaete, ha feela likarolo tsa elektroniki tse kang lipotoloho tse kopaneng li sebelisoa, li-PCB li sebelisoa bakeng sa khokahano ea motlakase lipakeng tsa tsona.

PCB le PCBA ke PCBs le likarolo unmounted, PCBA (Printed Circuit Board Assembly), ke hore, PCBs a hlomelloa le likarolo tsa elektronike (tse kang lichifi, dikgokelo, resistors, capacitors, inductors, joalo-joalo).

Tšimoloho ea PCB

Ka 1925, Charles Ducas oa United States (moqapi oa mokhoa oa ho eketsa) o ile a hatisa mokhoa oa potoloho holim'a substrate e sireletsang, 'me ka katleho a etsa mokhanni e le mohala ka electroplating.

Ka 1936, Paul Eisler oa Austria (moqapi oa mokhoa oa ho tlosa) e bile eena oa pele oa ho sebelisa liboto tsa potoloho tse hatisitsoeng liea-le-moeeng.

Ka 1943, Maamerika a ile a sebelisa theknoloji ho seea-le-moea sa sesole. Ka 1948, United States e ile ea amohela ka molao boqapi boo bakeng sa tšebeliso ea khoebo.

Liboto tsa potoloho tse hatisitsoeng li 'nile tsa sebelisoa haholo ho tloha bohareng ba lilemo tsa bo-1950,' me kajeno li laola indasteri ea lisebelisoa tsa elektronike.

Liboto tsa potoloho tse hatisitsoeng li ntlafalitse ho tloha ho lera le le leng ho ea ho tse peli, tse nang le mekhahlelo e mengata le tse tenyetsehang, 'me li ntse li boloka mekhoa ea tsona ea ntlafatso. Ka lebaka la tsoelo-pele e tsoelang pele ka tataiso ea ho nepahala ho phahameng, boima bo phahameng le ho tšepahala ho phahameng, ho fokotseha ho tsoelang pele ka boholo, ho fokotsa litšenyehelo le ntlafatso ea ts'ebetso, liboto tsa potoloho tse hatisitsoeng li ntse li boloka matla a matla ho nts'etsopele ea lisebelisoa tsa elektronike tse tlang.

Lipuisano mabapi le tsoelo-pele ea nakong e tlang ea theknoloji ea tlhahiso ea boto e hatisitsoeng lapeng le mose ho maoatle ha e le hantle li tsitsitse, ke hore, ho ba le letsoalo le phahameng, ho nepahala ho phahameng, sekoti se setle, terata e tšesaane, molumo o monyane, ts'epahalo e phahameng, marang-rang a mangata, phetiso ea lebelo le phahameng. , boima bo bobebe Mabapi le tlhahiso, e ntse e tsoela pele ka tsela ea ho eketsa tlhahiso, ho fokotsa litšenyehelo, ho fokotsa tšilafalo, le ho ikamahanya le mefuta e mengata le lihlahisoa tse nyenyane.

Mosebetsi oa PCB

Pele boto ea potoloho e hatisitsoeng e hlaha, ho hokahana pakeng tsa likarolo tsa elektronike ho ne ho hokahanngoa ka ho toba ka lithapo ho etsa potoloho e feletseng.

Ka mor'a hore lisebelisoa tsa elektronike li amohele liboto tsa potoloho tse hatisitsoeng, ka lebaka la ho lumellana ha liboto tsa potoloho tse hatisitsoeng tse tšoanang, liphoso tsa wiring ka letsoho li qojoa.

Boto ea potoloho e hatisitsoeng e ka fana ka ts'ehetso ea mochini bakeng sa ho lokisa le ho kopanya likarolo tse fapaneng tsa elektroniki joalo ka lipotoloho tse kopaneng, ho phethela mohala le khokahanyo ea motlakase kapa ho kenella ka motlakase lipakeng tsa likarolo tse fapaneng tsa elektroniki joalo ka lipotoloho tse kopaneng, le ho fana ka litšobotsi tse hlokahalang tsa motlakase, joalo ka litšobotsi tsa Impedance, joalo-joalo, e ka fana ka lits'oants'o tsa maske tsa solder bakeng sa solder ea othomathiki, le ho fana ka litlhaku tsa boitsebahatso le lits'oants'o bakeng sa ho kenya likarolo, ho lekola le ho hlokomela.

Sehlopha sa PCB

1. Ho arola ka sepheo

Liboto tsa potoloho tse hatisitsoeng ke sechaba (moreki): liboto tsa potoloho tse hatisitsoeng tse sebelisoang linthong tsa ho bapala, lik'hamera, lithelevishene, lisebelisoa tsa molumo, mehala ea cellular, joalo-joalo.

Liboto tsa potoloho tse hatisitsoeng tsa indasteri (lisebelisoa): liboto tsa potoloho tse hatisitsoeng tse sebelisoang ts'ireletso, likoloi, likhomphutha, mechini ea puisano, lisebelisoa, joalo-joalo.

Liboto tsa potoloho tse hatisitsoeng ke sesole: liboto tsa potoloho tse hatisitsoeng tse sebelisoang sebakeng sa sefofane le radar, jj.

2. Ho hlophisoa ka mofuta oa substrate

Liboto tsa potoloho tse hatisitsoeng ka pampiri: liboto tsa potoloho tse hatisitsoeng ka pampiri ea phenolic, liboto tsa potoloho tse hatisitsoeng tse thehiloeng pampiring ea epoxy, jj.

Liboto tsa potoloho tse hatisitsoeng tse thehiloeng ka lesela la khalase: liboto tsa potoloho tse hatisitsoeng tsa khalase ea epoxy, liboto tsa potoloho tse hatisitsoeng tsa khalase ea PTFE, jj.

Synthetic fiber e hatisitsoeng ka boto ea potoloho: boto ea potoloho ea epoxy synthetic fiber, joalo-joalo.

Boto ea potoloho e hatisitsoeng ea filimi ea Organic: boto ea potoloho e hatisitsoeng ea filimi ea nylon, jj.

Ceramic substrate hatisitsoeng potoloho mapolanka.

Metal core e thehiloeng mapolanka a potoloho hatisitsoeng.

3. Ho arola ka sebopeho

Ho ea ka sebopeho, liboto tsa potoloho tse hatisitsoeng li ka aroloa ka liboto tsa potoloho tse hatisitsoeng tse thata, liboto tsa potoloho tse hatisitsoeng le liboto tsa potoloho tse thata tse hatisitsoeng.

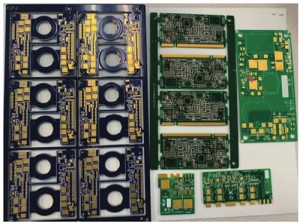

4. E arotsoe ho ea ka palo ea lihlopha

Ho ea ka palo ea lihlopha, liboto tsa potoloho tse hatisitsoeng li ka aroloa ka mapolanka a mahlakoreng a le mong, mapolanka a mahlakoreng a mabeli, mapolanka a mangata a mangata le mapolanka a HDI (mapolanka a marang-rang a phahameng).

1) Lehlakore le le leng

Boto e nang le lehlakore le le leng e bua ka boto ea potoloho e kentsoeng ka lehlakoreng le le leng feela (lehlakoreng la soldering) la boto ea potoloho, 'me likarolo tsohle, li-label tsa likarolo le li-labels tsa mongolo li behoa ka lehlakoreng le leng (lehlakoreng la karolo).

Ntho e kholo ka ho fetisisa ea phanele e nang le lehlakore le le leng ke theko ea eona e tlaase le mokhoa o bonolo oa ho etsa. Leha ho le joalo, kaha mohala o ka etsoa feela holim'a sebaka se le seng, mohala o thata haholoanyane, 'me mohala o atisa ho hlōleha, kahoo o loketse feela lipotoloho tse ling tse batlang li le bonolo.

2) Mahlakore a mabeli

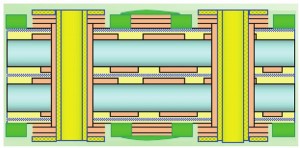

Letlapa le nang le mahlakoreng a mabeli le tšeloa ka mahlakoreng ka bobeli a boto ea insulating, lehlakoreng le leng le sebelisoa e le lera le ka holimo, 'me lehlakoreng le leng le sebelisoa e le lera le ka tlaase. Likarolo tse ka holimo le tse ka tlase li hoketsoe ka motlakase ka vias.

Hangata, likarolo tse holim'a boto ea lihlopha tse peli li behoa holim'a lera le ka holimo; leha ho le joalo, ka linako tse ling likarolo li ka behoa likarolong tse peli e le ho fokotsa boholo ba boto. Boto ea mekhahlelo e 'meli e khetholloa ka theko e itekanetseng le wiring e bonolo. Ke mofuta o sebelisoang ka ho fetisisa libotong tse tloaelehileng tsa potoloho.

3) Boto ea lihlopha tse ngata

Liboto tsa potoloho tse hatisitsoeng tse nang le likarolo tse fetang tse peli li bitsoa liboto tsa multilayer.

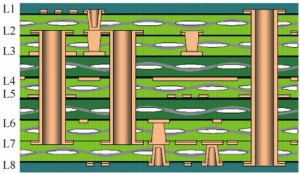

4) HDI boto

HDI boto ke boto ea potoloho e nang le palo e batlang e phahameng ea kabo ea potoloho e sebelisang theknoloji ea lesoba e sa boneng e nyane.

Sebopeho sa PCB

PCB haholo-holo e entsoe ka koporo clad laminates (Copper Clad Laminates, CCL), prepreg (PP sheet), koporo foil (Copper Foil), solder maske (eo hape e tsejoang e le solder maske) (Solder Mask). Ka nako e ts'oanang, e le ho sireletsa foil ea koporo e pepesitsoeng holim'a metsi le ho netefatsa phello ea welding, ho boetse hoa hlokahala ho etsa phekolo ea holim'a PCB, 'me ka linako tse ling e boetse e tšoauoa ka litlhaku.

1) Copper Clad Laminate

Copper-clad laminate (CCL), e bitsoang laminate ea koporo-clad kapa koporo-clad laminate, ke thepa ea motheo bakeng sa ho etsa liboto tsa potoloho tse hatisitsoeng. E entsoe ka lera la dielectric (resin, fiber ea khalase) le mokhanni oa bohloeki bo phahameng (foil ea koporo). e entsoeng ka lintho tse entsoeng ka motsoako.

E ne e se ho fihlela ka 1960 moo baetsi ba litsebi ba ileng ba sebelisa formaldehyde resin foil koporo e le thepa ea motheo ea ho etsa li-PCB tse nang le lehlakore le le leng, 'me ba li kenya' marakeng oa libapali tsa lirekoto, lirekoto tsa litheipi, lirekoto tsa video, joalo-joalo Hamorao, ka lebaka la ho phahama ha makhetlo a mabeli. -Sided through-hole koporo plating thekenoloji, ho hanyetsa mocheso, boholo Stable epoxy glass substrates li 'nile tsa sebelisoa haholo ho fihlela joale. Matsatsing ana, FR4, FR1, CEM3, lipoleiti tsa ceramic le lipoleiti tsa Teflon li sebelisoa haholo.

Hajoale, PCB e sebelisoang ka ho fetesisa e entsoeng ka mokhoa oa etching ke ho khetha etch ka boto ea likobo ea koporo ho fumana mokhoa o hlokahalang oa potoloho. Copper clad laminate haholo-holo e fana ka mesebetsi e meraro ea conduction, insulation le ts'ehetso holim'a boto eohle ea potoloho e hatisitsoeng. Ts'ebetso, boleng le litšenyehelo tsa tlhahiso ea liboto tsa potoloho tse hatisitsoeng li itšetlehile haholo ka li-laminate tsa koporo

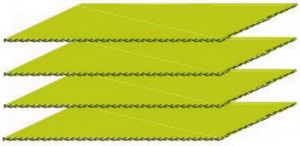

2) Prepreg

Prepreg, eo hape e tsejoang e le PP sheet, ke e 'ngoe ea lisebelisoa tse ka sehloohong tlhahisong ea liboto tsa multilayer. Haholo-holo e entsoe ka resin le lisebelisoa tse matlafatsang. Lisebelisoa tse matlafatsang li arotsoe ka lesela la khalase (lesela le bitsoang lesela la khalase), setsi sa pampiri le lisebelisoa tse kopantsoeng.

Boholo ba li-prepregs (matlapa a sekhomaretsi) a sebelisoang ha ho etsoa mapolanka a potoloho a hatisitsoeng a multilayer a sebelisa lesela la khalase e le thepa e matlafatsang. Thepa e tšesaane ea lakane e entsoeng ka ho kenya lesela la khalase e tšoaroang ka sekhomaretsi sa resin, ebe e apehoa pele ka kalafo ea mocheso e bitsoa prepreg. Li-prepregs li nolofatsa tlas'a mocheso le khatello 'me li tiisa ha li pholile.

Kaha palo ea likhoele tsa khoele ka bolelele ba yuniti ea lesela la khalase ka litsela tsa warp le weft li fapane, tlhokomelo e lokela ho lefshoa ho warp le weft directions ea prepreg ha u itšeha. Ka kakaretso, tataiso ea warp (taelo eo lesela la khalase le kobehileng ka eona) e khethoa e le tataiso e khutšoanyane ea lehlakoreng la boto ea tlhahiso, 'me tataiso ea weft ke Tataiso ea lehlakore le lelelele la boto ea tlhahiso ke ho netefatsa hore ho bata ha boto le ho thibela boto ea tlhahiso ho sotheha le ho holofala ka mor'a ho futhumatsoa.

3) Foil ea koporo

Lesela la koporo ke lesela le tšesaane, le sa khaotseng la tšepe le kentsoeng karolong ea motheo ea boto ea potoloho. Joalo ka mokhanni oa PCB, e hokelloa habonolo ho lera la insulating le ho emisoa ho theha mokhoa oa potoloho.

Lisebelisoa tse tloaelehileng tsa koporo tsa indasteri li ka aroloa ka mekhahlelo e 'meli: foil ea koporo e kolobisitsoeng (RA ea koporo ea koporo) le e entsoeng ka koporo ea electrolytic (ED koporo foil):

Foil ea koporo e phuthetsoeng e na le ductility e ntle le litšobotsi tse ling, 'me ke foil ea koporo e sebelisitsoeng ts'ebetsong ea pele ea boto e bonolo;

Electrolytic koporo foil e na le molemo oa theko e tlase ea tlhahiso ho feta foil ea koporo e phuthoang

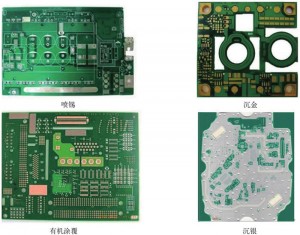

4) Mask ea solder

The solder hanyetsa lera e bua ka karolo ea hatisitsoeng boto potoloho le solder hanyetsa enke.

Solder resist inki hangata e tala, 'me ba seng bakae ba sebelisa bofubelu, ba batsho le boputsoa, joalo-joalo, kahoo solder hanyetsa inki hangata e bitsoa oli e tala indastering ea PCB. Ke lera le sa feleng le sireletsang la mapolanka a potoloho a hatisitsoeng, a ka thibelang mongobo, Anti-corrosion, anti-mildew le abrasion ea mechine, joalo-joalo, empa hape e thibela likarolo ho tloha ho cheselletsa libakeng tse fosahetseng.

5) Phekolo ea sefahleho

"Surface" joalo ka ha e sebelisitsoe mona e bua ka libaka tsa khokahano ho PCB tse fanang ka khokahano ea motlakase lipakeng tsa likarolo tsa elektroniki kapa lits'ebetso tse ling le li-circuits tse ho PCB, joalo ka libaka tsa khokahano ea li-pads kapa likhokahano tsa likhokahano. The solderability ea koporo e se nang letho ka boeona e ntle haholo, empa e na le oxidized habonolo mme e silafatsoa ha e pepesehile moeeng, kahoo filimi e sireletsang e lokela ho koaheloa holim'a koporo e se nang letho.

Mekhoa e tloaelehileng ea phekolo ea holim'a PCB e kenyelletsa lead HASL, HASL e se nang lead, coating organic (Organic Solderability Preservatives, OSP), khauta e qoelisoang, silevera e qoelisoang, thini ea ho qoelisoa le menoana e entsoeng ka khauta, joalo-joalo Ka ntlafatso e tsoelang pele ea melao ea ts'ireletso ea tikoloho, ho na le are Ts'ebetso ea HASL e etelletseng pele e thibetsoe butle-butle.

6) Litlhaku

Sebopeho ke mongolo oa mongolo, karolong e ka holimo ea PCB, e ka ba sieo, 'me hangata e sebelisoa bakeng sa litlhaloso.

Hangata, molemong oa ho tsamaisa ts'ebetso le tlhokomelo ea potoloho, lipaterone tsa logo tse hlokahalang le likhoutu tsa mongolo li hatisoa libakeng tse kaholimo le tse tlase tsa boto e hatisitsoeng, joalo ka li-label tsa likarolo le boleng ba mabitso, sebopeho sa likarolo le li-logos tsa moetsi, tlhahiso. matsatsi ema.

Hangata litlhaku li hatisoa ka khatiso ea skrine

Nako ea poso: Mar-11-2023