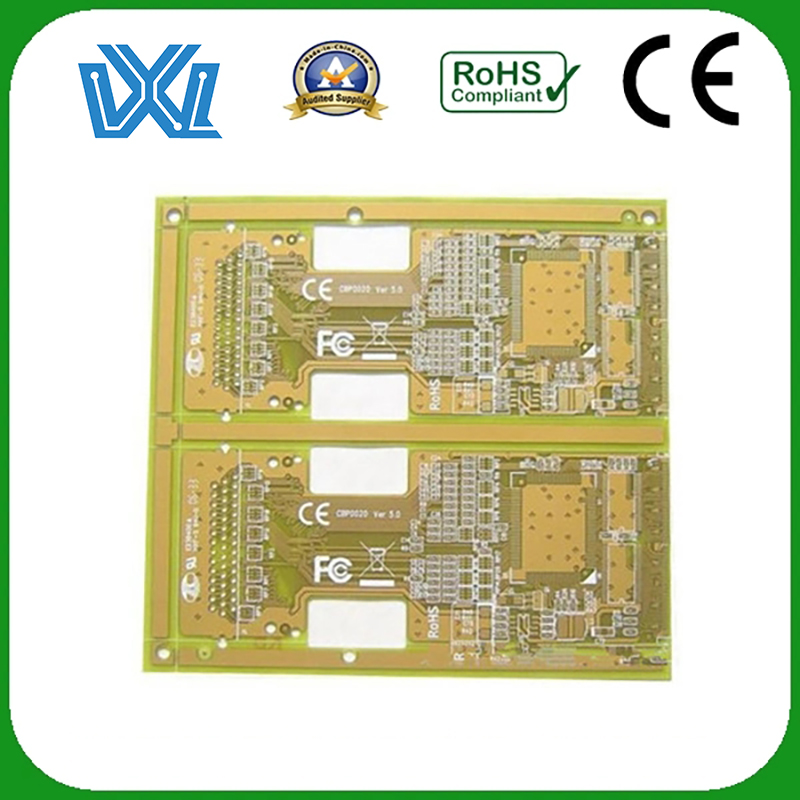

PCB Assembly oo la habeeyey iyo PCBA

Sharaxaada

| Qaabka NO. | ETP-005 | Xaalad | Cusub |

| Nooca Alaabta | PCB Assembly iyo PCBA | Daloolka Min | 0.12mm |

| Midabka Maaskarada Alxan | Cagaar, Buluug, Cadaan, Madow, Jaalle, Casaan iwm Dhamaystir dusha sare | Dhamaystir dusha sare | HASL, Enig, OSP, Far dahab ah |

| Min Raad Ballaadhka/Baaxadda | 0.075/0.075mm | Dhumucda Copper | 1 - 12 Oz |

| Hababka Golaha | SMT, DIP, iyada oo loo marayo dalool | Goobta Codsiga | LED, Caafimaadka, Warshadaha, Guddiga Xakamaynta |

Ku saabsan Naqshadeynta Guddigayada PCB

Marka aan naqshadeyno guddiga PCB, waxaan sidoo kale haysanaa xeerar: marka hore, habeyno boosaska ugu muhiimsan ee habka signalka, ka dibna raac "wareegga marka hore waa adag yahay ka dibna sahlan, mugga qayb ka mid ah weyn ilaa yar, calaamad xoog leh iyo kala-soocidda calaamadaha daciifka ah, sare iyo hoose. Calaamado kala duwan, calaamadaha analoogga iyo dhijitaalka ah ee goonida ah, isku day inaad ka dhigto fiilooyinka sida ugu gaaban ee suurtogalka ah, oo ka dhig qaabka mid macquul ah intii suurtogal ah"; waa in fiiro gaar ah loo yeeshaa si loo kala saaro "dhulka isha" iyo "goobta korontada"; Tani waxay inta badan tahay in laga hortago dhul korontadda Khadka mararka qaarkood wuxuu leeyahay qulqul weyn oo dhex mara. Haddii wakhtigan xaadirka ah lagu soo bandhigo terminalka signalada, waxa ay ka muuqan doontaa terminalka wax soo saarka iyada oo loo marayo chip-ka, sidaas awgeed waxay saamaynaysaa waxqabadka nidaaminta korantada ee sahayda wareejinta.

Kadibna, booska habaynta iyo jihada fiilooyinka ee qaybaha waa in ay ahaataa sida ugu macquulsan ee fiilooyinka jaantuska wareegga, taas oo noqon doonta mid aad u habboon dayactirka dambe iyo kormeerka.

Siliga dhulku waa inuu noqdaa mid gaaban oo ballaadhan intii suurtagal ah, siliga daabacan ee dhex mara tamarta beddelka ah waa in sidoo kale la ballaariyaa intii suurtagal ah. Guud ahaan, waxaan leenahay mabda'a marka fiilooyinka, siliga dhulka waa ka ugu ballaaran, silig koronto waa labaad, iyo silig signal waa ka cidhiidhi ah.

Yaree wareegga jawaab-celinta, gelinta iyo wax-soo-saarka sixitaanka aagga wareegga wareegga inta ugu badan ee suurtogalka ah, ujeedadani waa in la yareeyo faragelinta sawaxanka ee sawaxanka beddelka.

Hal-joojin Xalka

Aaladaha wax soo saara sida kuleyliyeyaasha waa in laga fogeeyaa inta suurtogalka ah ilaha kulaylka ama aaladaha wareegga ee keena faragelinta.

Fogaanta isdhaafsiga ah ee u dhaxaysa chips-yada laba-in-line waa in ay ka weyn tahay 2mm, masaafada u dhaxaysa caabiyaha chip iyo capacitor-ga waa in uu ka weynaadaa 0.7mm.

Capacitor filter filter waa in la dhigaa sida ugu dhow ee suurtogalka ah ee khadka u baahan in la sifeeyo.

Nakhshadeynta guddiga PCB, dhibaatooyinka ugu caansan waa xeerarka badbaadada, EMC iyo faragelinta. Si loo xalliyo dhibaatooyinkan, waa in aan fiiro gaar ah u yeelannaa saddex arrimood marka la naqshadeynayo: masaafada booska, masaafada creepage iyo fogaanta dhexgalka dahaarka. Saamaynta

Tusaale ahaan: Masaafada Creepage: marka danabku uu yahay 50V-250V, LN ee fiyuuska ka horreeyaa waa ≥2.5mm, marka danabku yahay 250V-500V, LN ee fiyuuska hortiisa waa ≥5.0mm; nadiifinta korantada: marka danabku uu yahay 50V-250V, L-N ≥ 1.7mm ee fiyuuska hortiisa, marka danabku yahay 250V-500V, L-N ≥ 3.0mm ee fiyuuska hortiisa; wax shuruud ah looma baahna fiyuuska ka dib, laakiin isku day inaad fogaato gaar ah si aad uga fogaato dhaawaca wareegga gaaban ee korontada; Qeybta hoose ee AC ilaa DC ≥ 2.0 mm; dhinaca hoose ee dhulka DC ilaa dhulka ≥4.0mm, sida dhinaca hoose ee dhulka; dhinaca hoose ilaa kan sare ≥6.4mm, sida optokoupler, capacitor Y iyo qaybaha kale ee ka kooban, kala dheeraynta biinku way ka yar tahay ama la mid tahay 6.4mm in la gooyo; transformer laba-marxalad ≥6.4mm ama ka badan, ≥8mm dahaarka la xoojiyay.

Bandhiga Warshada

FAQ

Q1: Sideed u hubisaa tayada PCB-yada?

A1: PCB-yadayada dhamaantood waa 100% imtixaan oo ay ku jiraan Imtixaanka Baadhitaanka Duullimaadka, E-tijaabada ama AOI.

Q2: Waa maxay wakhtiga hogaanka?

A2: Tusaalaha waxay u baahan tahay 2-4 maalmood oo shaqo, wax soo saarka ballaaran wuxuu u baahan yahay 7-10 maalmood oo shaqo. Waxay kuxirantahay faylalka iyo tirada.

Q3: Ma heli karaa qiimaha ugu fiican?

J3: Haa. Si loo caawiyo macaamiisha inay xakameeyaan qiimaha waa waxa aan had iyo jeer isku dayeyno inaan sameyno. Injineeradayadu waxay bixin doonaan nashqada ugu fiican si loo badbaadiyo alaabta PCB.