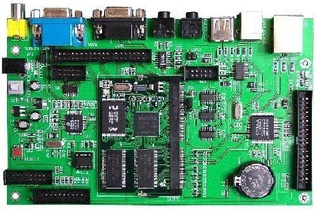

Tsarin PCBA: PCBA=Buga Majalisa Majalisar Da'ira, ma'ana, komai na PCB ya wuce ta babban ɓangaren SMT, sa'an nan kuma ya bi duk tsarin DIP plug-in, wanda ake kira tsarin PCBA.

Tsari da Fasaha

Jigsaw shiga:

1. Haɗin V-CUT: ta yin amfani da mai rarraba don tsaga, wannan hanyar tsagawa tana da ɓangaren giciye mai santsi kuma ba shi da wani tasiri a kan matakai masu zuwa.

2. Yi amfani da haɗin pinhole (ramin hatimi): Wajibi ne a yi la'akari da burr bayan raguwa, kuma ko zai shafi aikin barga na kayan aiki akan na'ura mai haɗawa a cikin tsarin COB. Ya kamata kuma a yi la'akari da ko zai shafi hanyar toshewa da kuma ko zai shafi taron.

Kayan PCB:

1. Kwali PCBs kamar XXXP, FR2, da FR3 suna da matukar tasiri ga zafin jiki. Saboda nau'ikan haɓaka haɓakar thermal daban-daban, yana da sauƙi don haifar da kumburi, nakasawa, karaya, da zubar da fatar jan karfe akan PCB.

2. Gilashin fiber panel PCBs irin su G10, G11, FR4, da FR5 ba su da ɗanɗano kaɗan daga zafin SMT da zafin jiki na COB da THT.

Idan fiye da COB biyu. SMT. Ana buƙatar matakan samar da THT akan PCB ɗaya, la'akari da inganci da farashi, FR4 ya dace da yawancin samfuran.

Tasirin wayoyi na layin haɗin kushin da matsayi ta hanyar rami akan samar da SMT:

Wiring na kushin haɗin layin da matsayi na ta ramuka suna da babban tasiri a kan sayar da yawan amfanin ƙasa na SMT, saboda m kushin haɗin Lines da ta ramukan iya taka rawar "sata" solder, sha ruwa solder a cikin reflow tanda Go ( siphon da aikin capillary a cikin ruwa). Abubuwan da ke biyowa suna da kyau don ingancin samarwa:

1. Rage faɗin layin haɗin kushin:

Idan babu iyakance iya aiki na yanzu da girman masana'anta na PCB, matsakaicin nisa na layin haɗin kushin shine 0.4mm ko 1/2 nisa kushin, wanda zai iya zama ƙarami.

2. Zai fi dacewa a yi amfani da kunkuntar layin haɗi tare da tsayin da ba kasa da 0.5mm (nisa bai fi 0.4mm ko nisa ba fiye da 1/2 na kushin nisa) tsakanin gammaye da aka haɗa zuwa manyan-yanki conductive tube ( kamar jiragen kasa, jiragen wuta).

3. Ka guji haɗa wayoyi daga gefe ko kusurwa cikin kushin. Mafi dacewa, hanyar haɗin waya tana shiga daga tsakiyar baya na kushin.

4. Ta hanyar ramuka ya kamata a kauce masa kamar yadda zai yiwu a cikin pads na abubuwan SMT ko kai tsaye kusa da pads.

Dalili kuwa shine: ramin da ke cikin kushin zai jawo mai siyar zuwa cikin rami kuma ya sa mai siyar ya bar haɗin gwiwa; ramin kai tsaye kusa da kushin, koda kuwa akwai kyakkyawan kariyar mai koren (a cikin ainihin samarwa, buguwar mai a cikin kayan PCB mai shigowa ba daidai bane A yawancin lokuta), yana iya haifar da nutsewar zafi, wanda zai canza yanayin. saurin infiltration na solder gidajen abinci, haifar da kabari sabon abu a guntu aka gyara, da kuma hana al'ada samuwar solder gidajen abinci a tsanani lokuta.

Haɗin da ke tsakanin ta rami da kushin ya fi dacewa da kunkuntar layin haɗi tare da tsayin da ba kasa da 0.5mm (nisa bai fi 0.4mm ko nisa ba fiye da 1/2 na faɗin kushin).

Lokacin aikawa: Fabrairu-22-2023