Custom PCB Factories - Fr4 PCB Assembly Design Software Supported – Weilian Electronics

Custom PCB Factories - Fr4 PCB Assembly Design Software Supported – Weilian Electronics Detail:

Description

| Technical Requirement | Professional Surface-mounting and Through-hole soldering Technology |

| Various sizes like 1206,0805,0603 components SMT technology | |

| ICT(In Circuit Test),FCT(Functional Circuit Test) technology | |

| PCB Assembly With UL,CE,FCC,Rohs Approval | |

| Nitrogen gas reflow soldering technology for SMT | |

| High Standard SMT&Solder Assembly Line | |

| High density interconnected board placement technology capacity | |

| Other PCB Assembly Equipments | SMT Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4 |

| Reflow Oven: FolunGwin FL-RX860 | |

| Wave Soldering Machine: FolunGwin ADS300 | |

| Automated Optical Inspection (AOI): Aleader ALD-H-350B,X-RAY Testing Service | |

| Fully Automatic SMT Stencil Printer: FolunGwin Win-5 |

What is the difference between several sheets of glass fiber board, epoxy board and FR4 board

1. Different uses. The main raw materials for the production of circuit boards are alkali-free glass cloth, fiber paper, and epoxy resin. Glass fiber board: substrate fiberglass cloth, epoxy board: adhesive is epoxy resin, FR4: substrate cotton fiber paper. All three are fiberglass boards.

2. Different colors. Usually the epoxy board on the market is phenolic epoxy, yellow. Not for rigid circuit board substrates, electrical insulation purposes. FR4 is a pure epoxy sheet of NEMA standard, the normal color is dark green, which is the color of epoxy. There are also yellow ones. Generally speaking, yellow FR4 is called yellow material, and white (green) is called white material. FR4 is more expensive than epoxy board, and glass fiber board cannot confirm the price.

3. the nature is different. Glass fiber board has the characteristics of sound absorption, sound insulation, heat insulation, environmental protection, flame retardant and so on. FR-4 is also known as fiberglass board; fiberglass board; FR4 reinforcement board; FR-4 epoxy resin board; flame retardant insulation board; epoxy board, FR4 light board. Epoxy glass cloth board; circuit board drilling pad.

Epoxy board and glass fiber board contain active epoxy groups in the molecular structure, which can cross-link with various types of curing agents to form insoluble and infusible polymers with a three-way network structure.

First of all, in terms of composition, the main raw materials for the production of circuit boards are alkali-free glass cloth, fiber paper, epoxy resin

Fiberglass board: substrate fiberglass cloth

Epoxy board: The adhesive is epoxy resin

F R 4: Base material cotton fiber paper

In short, the epoxy boards on the market are usually phenolic epoxy, the yellow one, which is generally not used as a substrate for hard circuit boards, but for electrical insulation purposes.

FR4 is NEMA standard pure epoxy sheet, the normal color should be dark green, which is the color of epoxy. There are also yellow ones. Generally speaking, yellow FR4 is called yellow material, and white (green) is called white material.

One-stop Solution

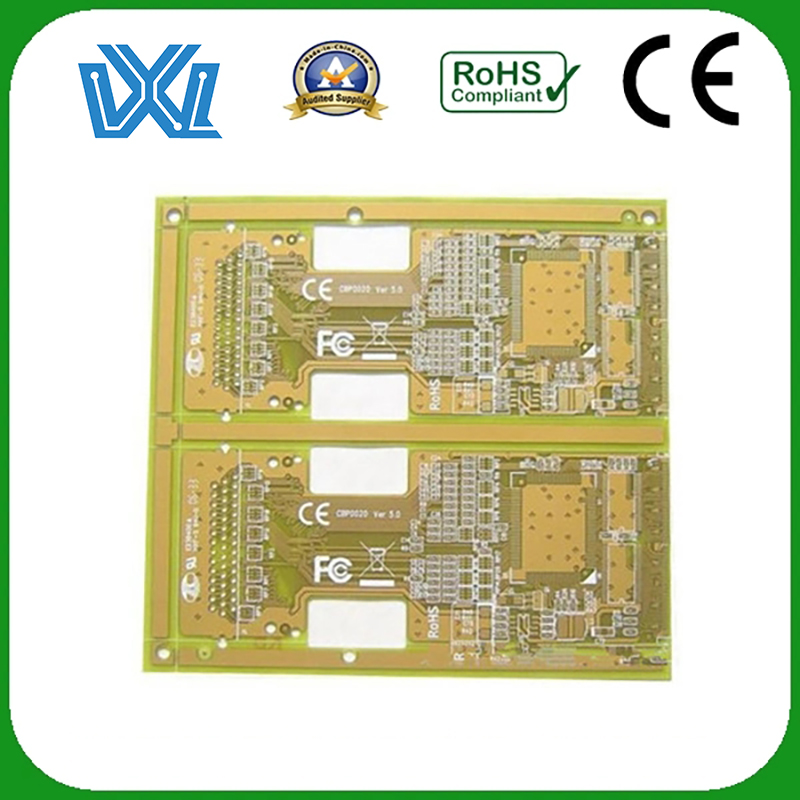

Product detail pictures:

Related Product Guide:

Sincerity, Innovation, Rigorousness, and Efficiency could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for Custom PCB Factories - Fr4 PCB Assembly Design Software Supported – Weilian Electronics , The product will supply to all over the world, such as: Houston, Armenia, Doha, We have more than 10 years experience of production and export business. We always develop and design kinds of novel products to meet the market demand and help the guests continuously by updating our products. We are specialized manufacturer and exporter in China. Wherever you are, please join us, and together we will shape a bright future in your business field!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.